TMVT INDUSTRIES P. LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to TMVT INDUSTRIES P. LTD.

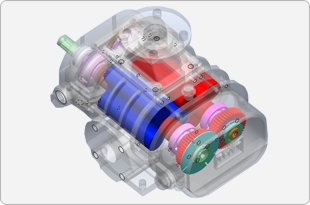

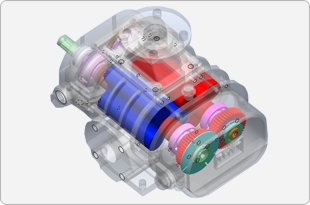

Three Lobe Roots Blower

Three Lobe Roots Blower :

TMVT Three Lobe Roots Blower are new 3MTL series Roots type Blower. Rotors are manufactured on high precision CNC machines ensuring high performance. Owing to ‘THREE LOBES' Rotor design, the reverse flow pressure variation period is only 2/3 of that of a conventional ‘TWO LOBES' rotor, the peak pressure is also lower. So the noise and pressure pulsation are greatly limited.

Features Of Three Lobe Roots Blower :

Discharge pressure pulsation is reduced, so lighter loading of bearings and timing gears ensures the long servicing life.

Oil Chamber is separated from main chamber. Hence air is oil free.

Bearings on drive and driven sides are lubricated by oil

Construction simple and hence easy maintenance.

Less back flow. Hence Volumetric Efficiency increased.

Stable air flow rate

Lower vibration. Less vibration transmitted through the lobe results approximately 20% longer bearing life

Three lobes design efficiently reduce noise by approximately 5dB

Twin Lobe Roots Blower

Salient Features of TMVT Compressors:

TMVT make Twin Lobe Compressors (MTLK / MP / ETP Series) are enjoying tremendous reputation in the market since about 3 decades.

Complete range of 18 Models of MTLK type covers requirements of various industries of divers nature.

Suitable for different pressure up to 1 Kg/cm2 in Single Stage and up to 2.2 Kg/cm2 in Double Stage. Also suitable for Gas Duty as well as Vacuum Duty (Up to 600 mbar).

Blower : The Main Body, Side Covers are manufactured from Graded Cast Iron as per CI IS 210 FG 260. Castings are procured from Foundries of repute like Bhagwati Spherocast, Ductile Iron Foundry, etc. etc.

Rotors : The Rotors are of S. G. Iron as per grade 400 / 015 of smaller capacities up to 1500 M3/ Hr. For larger capacities of Twin Lobe Compressors, Rotors are having Lobes in Graded Cast Iron IS 210 FG 260 Construction. All types of Rotors are with EN-8 Shafts.

Liquid Ring Vacuum Pump

Salient Features:

The Liquid Ring Vacuum Pump has certain advantages such as :

Material Of Construction: Considering corrosive conditions of gas to be handled, construction of vacuum pump is selected. It is available in complete cast iron, complete S.S., partial S.S. or partial bronze construction.

Vacuum: Up to 50 mm Hg. Absolute using service liquid as water at 30°C. and higher (with water having less than 30°C)

Higher Vacuum: Higher vacuum can be obtained by using special oil or other service liquid. Also high vacuum can be achieved by using Liquid Ring Vacuum Pump as backing pump in series with mechanical booster.

Long Life and Low Maintenance Cost. : Pumps are robust in construction. Impeller with shaft is only moving part. Impeller has no contact with casing. Hence wear is negligible. These machines require very little maintenance and easy overhauling.

Vibration- free and Noiseless Operation: The sealant ring acts as a sound damper. Gas flow is non-pulsation type. Hence machines are comparatively noiseless and vibration-free.

Liquid and Vapor Handling: Liquid Ring Vacuum Pumps are capable of handling large quantities of vapor. It has also ability to handle small amount of liquid in the suction stream without causing damage.

Handling solid particles: Continuous flushing action permits handling of certain fibrous materials

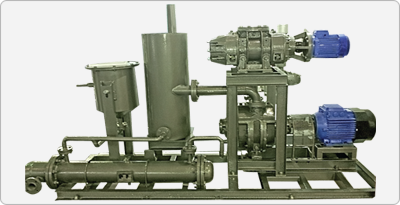

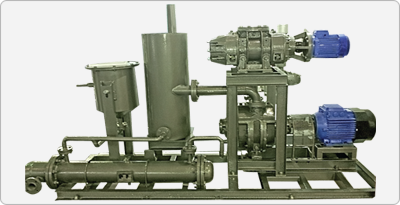

High Vacuum System

TMVT Mechanical Booster Vacuum Systems are designed engineered and manufactured in our State-of-the – art modern manufacturing facility. Systems are suited to a wide range of applications.

A vacuum Booster can be backed by various types of Vacuum pumps such as Liquid Ring Vacuum Pump, Rotary oil sealed, Rotary piston, Reciprocating piston pump, Dry screw pumps, water/steam ejectors etc.

Liquid Ring Vacuum systems can be configured with Lobe type Boosters to maximize flow at lower vacuum levels. Equipped with single stage liquid ring backing pumps, the systems are offered as air cooled models. These are available in Direct Driven versions with or without VFD Drive wherein capacity can be varied as per the choice. Each system is specifically designed to meet customer’s requirements for capacity, final vacuum and material of construction.

The systems operate initially with the vacuum pump pulling down to maximum vacuum, followed by the cut in of the booster to maximize the flow.

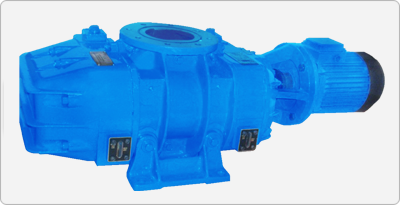

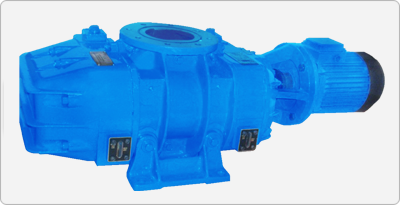

Mechanical Vacuum Boosters

Mechanical Vacuum Boosters:

TMVT Vacuum Boosters dramatically reduce process time by achieving faster evacuation. They also reduce power requirements. It can also achieve higher values of vacuum, if required. TMVT manufactures wide range of capacity Booster pumps in India. Capacities range from 270 to 5240 M³/Hr.

TMVT Industries Pvt. Ltd. is an ISO 9001-2008 company.

Salient Features of TMVT Boosters:

Very high volumetric pumping efficiency and capable of moving large quantity of gas at low pressures.

Provide significant savings in time and power.

Can be used in combination with variety of backing vacuum pumps to achieve higher speeds and lower ultimate pressures.

As an oil free pump, the mechanical booster delivers clean and dry gas.

Backing pumps to achieve low pressures with high pumping speeds.

Rotors are made on CNC machines to close tolerances and are dynamically balanced.

High quality bearings for longer life and trouble free operation.

All units are leak tested.

Suited to a wide range of applications.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.